A Simple Guide to How This Modern Modular Cabin Is Built

The Apple Cabin is a stylish and flexible prefab unit used in resorts, campsites, offices, and more. You may have seen pictures of it online or in real life—but do you know how it’s actually made?

In this article, we’ll walk you through how a typical Apple Cabin is built inside the factory—from the first drawing to final delivery. This step-by-step process shows how fast, efficient, and professional modern prefab construction can be.

Every Apple Cabin begins with a custom layout. Based on the customer’s use—like a guest room, office, or retail shop—we create:

A floor plan layout

Drawings for the exterior and interior

Plans for electricity and plumbing

A list of materials

At Sunfine, our team provides free Apple Cabin layout suggestions to help you get the most practical and comfortable space.

Step 2: Getting Materials Ready

Once the design is confirmed, we prepare everything needed to build the apple cabin, including:

Steel beams for the frame

Wall panels and insulation

Wires, pipes, and bathroom fixtures

Floor, wall, and ceiling materials

By preparing everything in advance, we can build faster with fewer errors.

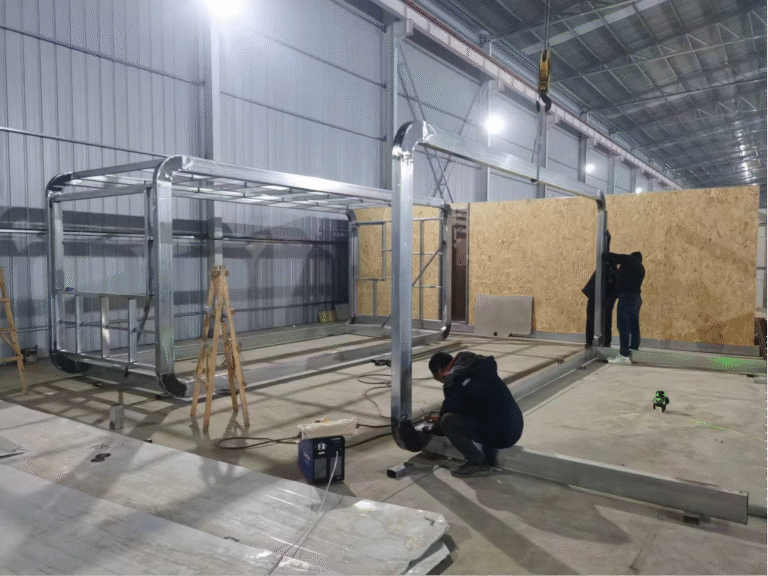

Step 3: Building the Steel Frame

Step 4: Adding the Walls and Insulation

Now we start forming the cabin shell:

We cover the frame with OSB boards

Then we fill the walls with XPS insulation board to keep the cabin warm in winter and cool in summer

After that, we install the exterior wall finishes. You can choose from carved metal panels, aluminum composite boards, or wood-look panels—all customizable by Sunfine

This is one of the key reasons the Apple Cabin performs well in extreme climates.

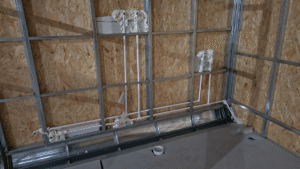

Step 5: Installing Water and Electricity

Step 6: Decorating the Inside

Step 7: Final Check and Shipping

Built for Global Projects

Apple Cabins made by Sunfine are now used in many countries, including Australia, New Zealand, and parts of Europe. They are perfect for:

Resorts and campsites

Pop-up shops and cafes

Offices or mobile homes

Showrooms or customer service booths

Sunfine provides flexible customization and supports projects of all sizes.

Conclusion

The Apple Cabin is more than just a prefab house—it’s a smart, ready-to-use solution that saves time, labor, and construction costs. Built in a controlled factory environment, it offers modern design, strong structure, and fast delivery.

If you’re planning a new resort, rental business, or want a portable office, the Apple Cabin is worth considering.

Get in Touch

Want to know more about apple cabin layout options, pricing, or shipping?

Contact Sunfine, your trusted prefab cabin supplier in China.